The field of tech is always evolving, allowing many different sectors to enhance operations, including the manufacturing industry. Over the last few years, many different technologies have gained prevalence in the manufacturing sector. To gain a better understanding let’s explore some of the key tech areas.

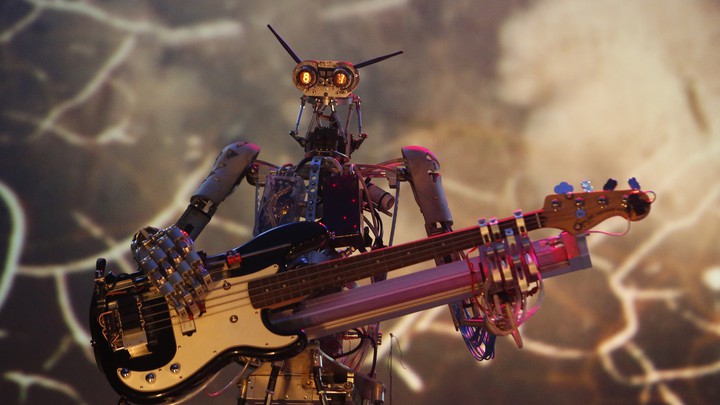

1 . Robotics

Robots are used in many different ways in the manufacturing sector, for example:

Assembly tasks

Assembling product parts is often repetitive, using robots can reduce human error and streamline the process.

Handling material

Robots can be used to handle materials that could be hazardous, or require an incredibly steady hand. Robots are also useful to handle materials that could become contaminated by humans.

Robotic automation can also be used to support the shipping processes, product packing, or welding tasks. There are plenty of benefits to using robotic automation in the manufacturing industry from saving time to improving the efficiency of operations.

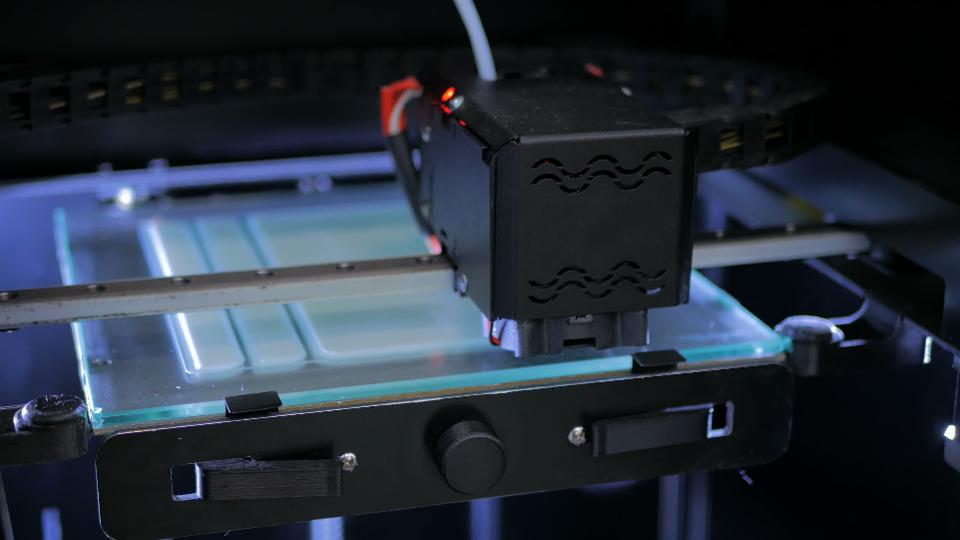

2. 3D Printing Processes

3D printing is a process that creates objects to meet a digital 3D model. When you use a 3D printer it’s possible to add materials in various layers, whether you’re using metals or plastics. With the help of 3D printing, it’s possible to produce complex components quickly. Using 3D tech manufacturers can ensure quality processes across different applications and sectors. Other benefits of 3D printing include rapid prototyping, on-demand printing, less waste, and saving money. Companies across many different niches are using 3D printing tools to improve the performance and quality of their products.

3. IoT Investment

Rockwell Automation’s VP recently stated that ‘With the IIoT market expected to grow from $77.3 billion in 2020 to $110.6 billion by 2025, 73% of manufacturers plan to increase their investment in smart factory technology over the next year, (Keith Higgins, Forbes 2021).

The IoT has plenty of different applications in the manufacturing sector. IoT can support production flow, and IoT devices can track development cycles automatically. Such devices can also be used to organize inventories and warehouses. Investment in IoT is steadily increasing and we can expect these trends to continue into 2022 and beyond. As these trends develop, manufacturing companies will need edge computing devices, for example, a single-board computer, offering improved performance at a reduced size.

4. VR & AR

The pandemic created difficulties for many manufacturing services. At one point technicians could not attend sites to make repairs or installations. Virtual reality and augmented reality allows technicians to offer remote support, for simple troubleshooting tasks. Previously, many consumers were slightly reluctant to try such service options. The events of COVID-19 have meant that many people are more willing to adopt new services. Manufacturers now have the opportunity to develop further technologies and processes which support a remote service model.

These are just a few ways that tech is influencing the manufacturing sector. As time goes on it’s likely that the industry will experience further tech advancements, to streamline the current processes. There are plenty of different business technologies to help your company succeed.