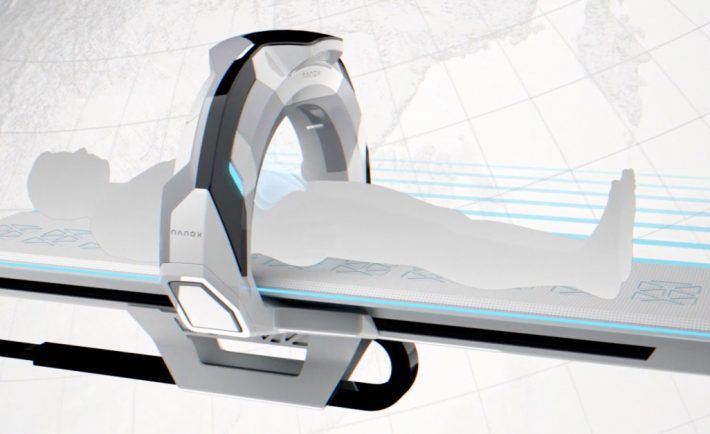

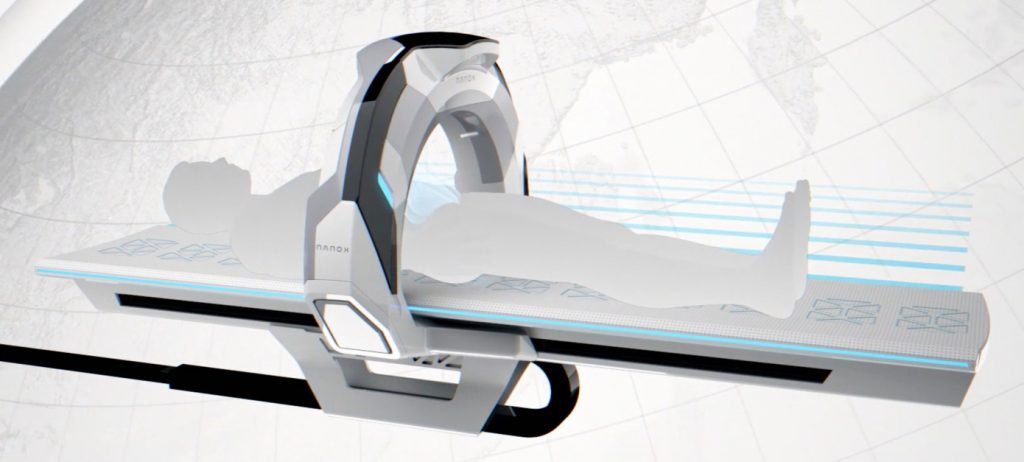

Do you consider yourself an x-ray guru? Imaging technology has grown in leaps and bounds in the recent past. As a result, it has diversified its usage in the engineering and medical world through Computed Tomography (CT) techniques. In depth and microscopic analysis of up to the micrometer is made possible by the microCT and medical CT scanners in any microscopy lab. Sample parts and circuitry in manufacturing industries can be analyzed using noninvasive measures. The time taken and resolution offered by these techniques are superior to any current methods in use. Consequently, it has had a significant impact on reducing production time and losses.

Interchangeability

Interestingly, the interchangeability and usage of the specialized machines are still in their early exploration phase. The medical CT can handle some engineering functions with great success. However, the results from the machines may and will differ depending on your expectations. There are several determining factors of an exemplary imaging technique.

1. Accuracy

Accuracy is an essential component of any analyzing tool. The machine should be able to translate the required information with exact precision. In engineering, measurements, defects, and it’s the resemblance to the envisioned piece are given the highest priority. Both Medical and industrial CTs use the same principles when manufactured. Due to the industries’ specialization, a few tweaks have been installed to best suit their functions, as mentioned earlier. For pinpoint accuracy of industrial test samples, it is advisable to use micro CTs as their accuracy is second to none.

2. Quantity

Quantity refers to the number of test elements or their sizes. The workability of the machines within a given time duration can be a hindrance to productivity. Having specialized CTs in industrial CTs gives it an edge at this point. They can take larger objects and give a more profound analysis with the same accuracy. On the other hand, Medical CTs can handle large volumes while maintaining the standards.

3. Resolution

How small a sample do you want the machine to go? The magnification of your machine determines the most significant resolution you can give. The higher the resolution, the greater the results. More extensive and denser objects are better analyzed using the industrial CT to combine accuracy and resolution with significant effect.

4. Time

How long will the machines take to finish the analysis? Time is an invaluable commodity. While you can forego time for performance standards, it is vital to get a machine that has a higher analysis rate without compromising standards. It will go hand in hand with the test quantity.

5. Pricing

Finally, how deep are you willing to dig into your finances? Are you willing to compromise on any of the above factors? Think long and hard about what you want and the expectations of your results. Have solutions ready in case of any unusual scenario—research widely on unconventional ways of balancing quality and finances. You will be surprised at the deals that are in store for you!

These are the top features that you should consider in any imaging lab. They guide you on which to purchase and when to outsource some services if necessary. Remember, this is a growing industry. Continually strive to evolve your knowledge of imaging technology.