Manufacturing is an industry of minute details. If one thing is slightly off, it can have huge implications for the efficiency of an operation over the long term. It’s essential for manufacturers to minimize inefficiencies if they want to maximize profitability. The best way to do this is through the collection and mobilization of manufacturing analytics. Here are five key performance indicators (KPIs) essential to manufacturing businesses.

Reject Rate

When running a manufacturing business, it’s essential to minimize waste. If your production line is creating an abnormally high number of faulty products, it’s a sign that you need to change something. However, if you aren’t keeping track of your reject rate, it might not be entirely clear to you that there’s an issue in your processes. To calculate the reject rate, simply divide the number of erroneous products by the total number. For example, if you make 1,000 widgets, and 10 are rejected, your reject ratio would be one percent.

Production Rate

Do You Know How to Determine Your Manufacturing Productivity Rate?

It’s important to find a healthy equilibrium rate for producing goods. If your machines and workers are going too fast, you’re running a higher risk of faulty products or injuries. However, going too slow will diminish your returns. You need to play the role of Goldilocks, and find the production rate that’s just right. It’s crucial that you use some form of real-time manufacturing analytics data collection system to automatically log the time it take to complete each item that goes through your factory. Unidentified deviations in production rate can have disastrous consequences.

Average Production Cost

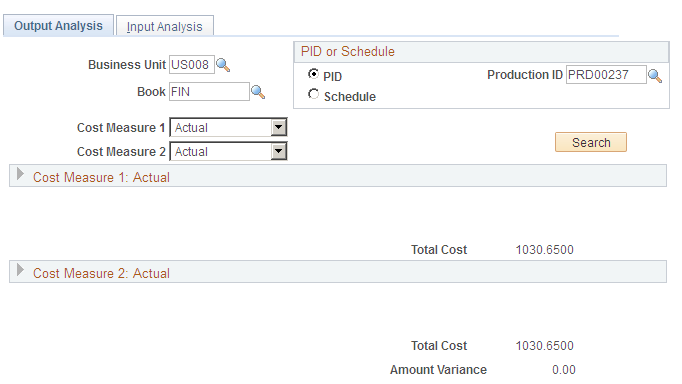

Reviewing Actual and Average Costing for Manufacturing

At the end of the day, you need to know how much it costs you to produce an item. This, however, isn’t as simple as adding up the cost of all the parts. You need to factor in several variables to truly understand average production cost, such as labor costs, energy costs, machinery costs, and maintenance costs. Your manufacturing protocol may require even more aspects to be included in this to get an accurate picture of average production cost. You will want to use manufacturing analytics to simplify this process as much as possible. It’s easy to get a misguided picture of your business’s health if you fail to accurately calculate average production cost.

Takt Time

Although it looks more like a typo than a legitimate KPI, Takt time is an important metric for a manufacturing company. Takt time can be used about many processes within the assembly procedure. Essentially, it’s a measurement of how long it takes to complete a certain operation. This term is often confusing for people because it can refer to several different things at the same time. Takt time can be measurement of how long it takes to complete a whole product. But it also can be about a single step, or sequence of steps, in the production line. Takt time is useful because it can identify where manufacturers are losing time in the assembly process, slowing down production rate. This can often be remedied by using data to determine how to reallocate resources.

Count

It may be one of the simplest of all KPIs, but that doesn’t mean it’s not important. Count is just the number of a good produced over a certain period. Individual manufacturers can determine the timeframe based on what they consider to be the best fit for their own goals. Regardless of unique methodology, it’s always a good idea to keep an eye on total output over a given period.

It’s essential that manufacturers strive to stay on top of KPIs. Failing to monitor these numbers can lead to a loss of profit, or potentially disaster.