(Image Source: Shutterstock)

(Image Source: Shutterstock)

“AI is creating tremendous economic value today.”

– Andrew Ng

Artificial Intelligence or AI is seen by many as a catalyst for driving new forms of innovation and more unique ways to build markets. According to a survey of IT and business executives conducted by Infosys, approximately 55% of the respondents see AI as an innovative mechanism to create improved, cost-efficient services, products, and business models.

Moreover, 42% feel that AI can help with greater personalization while 50% believe that it can help with a prompter resolution of problems.

Thus, in 2018, Rolls-Royce too decided to get onboard the AI wave with the launch of its IntelligentEngine initiative. The new initiative focuses on the development of intelligent aircraft engines that are more efficient and safer.

These ‘smart’ engines will be able to communicate in real time with each other and their support networks but will also learn from their experience courtesy advanced data analytics and Artificial Intelligence.

Introduced as an engine maintenance service backed by intelligent sensors, however, IntelligentEngine aims to serve a broader purpose in the future. According to Rolls Royce, the strategy will allow the engines to be ‘aware’ of their environment and operating context.

Let us see how the IntelligentEngine strategy would help the company improve the power delivery mechanism of their engines and how Rolls Royce sets an example for businesses looking to enhance their data storage functionalities.

The Exciting New World of Smart Engines

Rolls Royce envisions the engines of tomorrow to be able to continuously communicate two-ways with the other parts of the service ecosystem. Therefore, the IntelligentEngine strategy frames a near-future possibility, wherein an engine would be contextually aware, more understanding and connected to offer better efficiency and reliability.

That said, the strategy also delves deeper into designing, maintenance and testing of engines in the digital space. These smart engines will be contextually aware of responding to their surroundings without any human intervention.

According to the manufacturers, the IntelligentEngine initiative (currently being tested for aircraft), will enable engines to learn from their own experiences and network of peers. These smart engines could also undertake behavior adjustment to optimize their performance.

Moreover, the initiative is backed by R2 Data Labs, which is the acceleration hub of Rolls Royce designated for data innovation.

Along with product development, the center is also responsible for developing sophisticated industrial AI and conduct data analytics and machine learning research.

The Role of Sensors and Telemetry Data in Designing Futuristic Capabilities

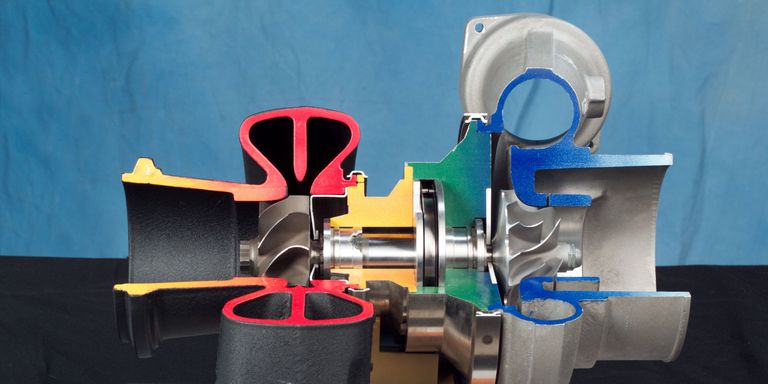

Earlier in 2016, Bombardier showcased its C Series jetliner at the Paris Air Show. The C Series aircrafts each carried the Pratt & Whitney’s Geared Turbo Fan (GTF) engine, fitted with 5,000 sensors.

Reportedly, these sensors may generate up to 10 GB of data per second. Therefore, if you consider a single twin-engine aircraft, with an average flight time of 12 hours per day, the engine sensors could generate up to 844 TB of telemetry data every day.

Now imagine a fleet of 1000 aircraft, each fitted with engines having 5000 sensors or more, and you are looking at potentially millions of terabytes of data generated in a 24-hour duration!

The 2016 MRO forecast by Oliver Wyman also estimated that the annual telemetry data generation of these aircraft is likely up to 98 million terabytes by the year 2026. Moreover, aircraft fitted with the newest generation engines could potentially generate between five and eight terabytes of data per flight.

So, the question arises – Where and How Will Aviation Companies Store that Data?

With increasing data levels, enterprises need to invest in more and more localized data centers. Having a localized data center will help achieve the following functionalities:

- Secure infrastructure for acquisition, storage, and transmission of data

- Report generation based on recorded and off-loaded full-flight data from the engines to a remote ground station

- Quick delivery of large datasets from the air to the ground

- Improved cycle time and preventative maintenance activities of the aircraft

The Growing Need for Colocation Data Centres

Overall, it is true that businesses of today can no longer neglect the potential of user-generated data or the impact of new-age tools such as AI and data analytics on business process automation.

Data center colocation facilities too have a part to play in the rising demand for AI-driven business solutions.

To cater to this rising demand for localized data storage and maintenance, reputable global players such as STT GDC India are developing state-of-the-art data centers in India. These data center colocation facilities provide cost-effective, reliable and secure solutions to businesses.