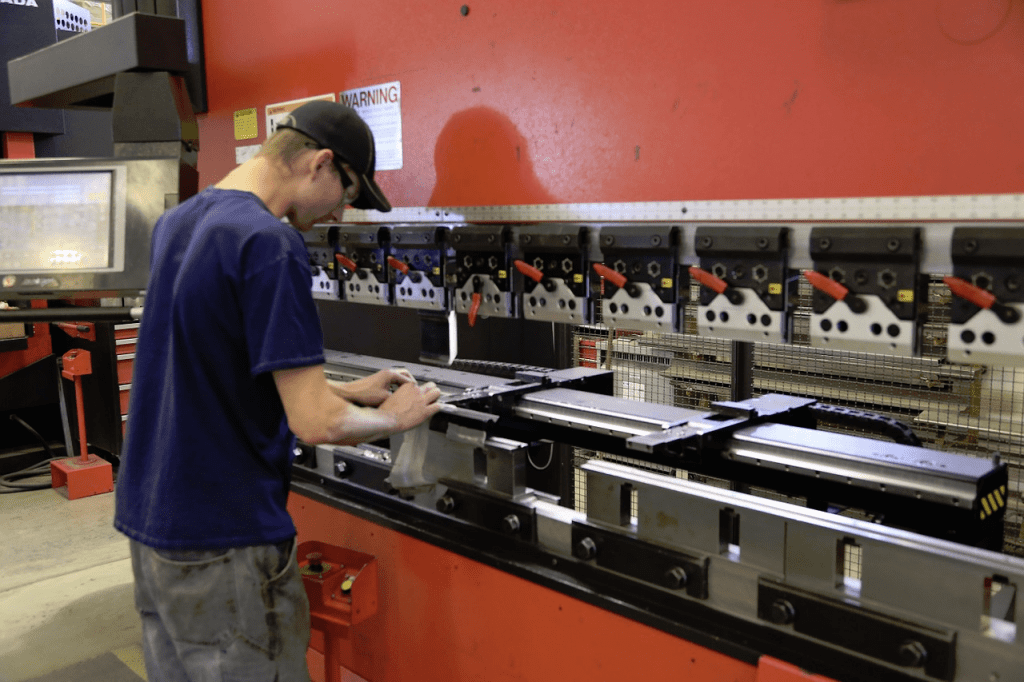

Metal fabrication is a process which involves a number of different pieces of equipment, of which press brakes are one of the most widely used options.

Of course unless you are already an industry insider, you might not know how a press brake works or what it can be used to achieve.

To remedy this, here is a quick overview of the technology underpinning press brakes and the contexts in which they will prove most impactful.

The basics

Whether you are buying new or considering the used press brakes for sale online at the moment, the principles underpinning the way these machines work are the same.

There are four main components at work, with each being used to bend and shape sheet metal into the desired form.

Up top, a ram with a punch mounted on it is forced downwards onto the material from above, while below a bed with a die affixed to it acts as the element which shapes the metal to a specific angle.

Modern machines which make use of CNC tech will also have integrated control units, allowing for impressive precision and accuracy, derived from whatever CAD files have been cooked up by the design team.

The varieties

There are four main ways in which press brakes can be operated, with the bending force either powered mechanically, pneumatically, hydraulically or via electric motors.

Mechanical, crank-driven press brakes are the most basic and old-fashioned of the bunch, and were effectively superseded by hydraulic press brakes in the middle of the last century.

Press brakes can also be further subdivided into machines which move the ram and punch downwards into the die and bed, and those which move it upwards. The orientation will depend on the needs of the manufacturer.

The rise of automation

It is worth noting that computerisation of press brakes has brought with it a significant degree of automation, as hinted at when discussing CNC equipment earlier.

This is significant because it makes the process of using this machinery far more efficient and precise, while driving down the likelihood of errors occurring or mistakes being made by human operators.

Furthermore as press brake technology has moved into the modern, digital era, safety has been demonstrably improved. It is even possible for equipment of this kind to operate almost entirely independently of direct worker intervention, keeping human employees out of harm’s way while mass production workloads are undertaken.

Clearly there is a price to pay for automation, and the difference between a CNC-equipped unit and one which needs to be controlled in a more manual, hands-on manner can be significant. Variations in cost also rely on the amount of force that the machine can exert, and thus the kinds of materials with which it can be used.

Now that you have the foundations of an understanding of press brake technology, you should be better equipped to study this subject further and even find equipment of this kind for your own business without being baffled.