Automating machine tending tasks can add value to your business in different ways.

Evaluating these ideas and integrating best practices with advanced robots will help eliminate inefficiencies, making way for a productive future.

Robotic machine tending structures offer various productivity advantages such as low operational costs and excellent machine utilization in different applications.

Today, the market is experiencing a rise in low volume high mix production. This trend has forced both small and medium-sized manufacturers to consider robotic automation to meet customer demands.

To identify a balance in the face of advanced technologies and robots, entrepreneurs will need to make the following considerations.

Industrial Robots

The demand for space-saving, fast, and easy to install, move, operate, and maintain industrial robots is on the rise.

These units promise to increase uptime and productivity to manufacturers regardless of their size.

Today, some advanced robots come complete with higher ingress protection wrist ratings. These facilitate protection against cutting fluids.

Further, they come with higher inertia ratings to enhance large part handling performance which helps conquer challenges.

The increasing use of lightweight and small six-axis robots is another developing trend. These robots are designed to support various sensors and tools to cater to the needs of varied machine tending requirements.

They also facilitate mounting near machinery and work pieces in existing cells and lines. Businesses can utilize these robots to cut down cycle times.

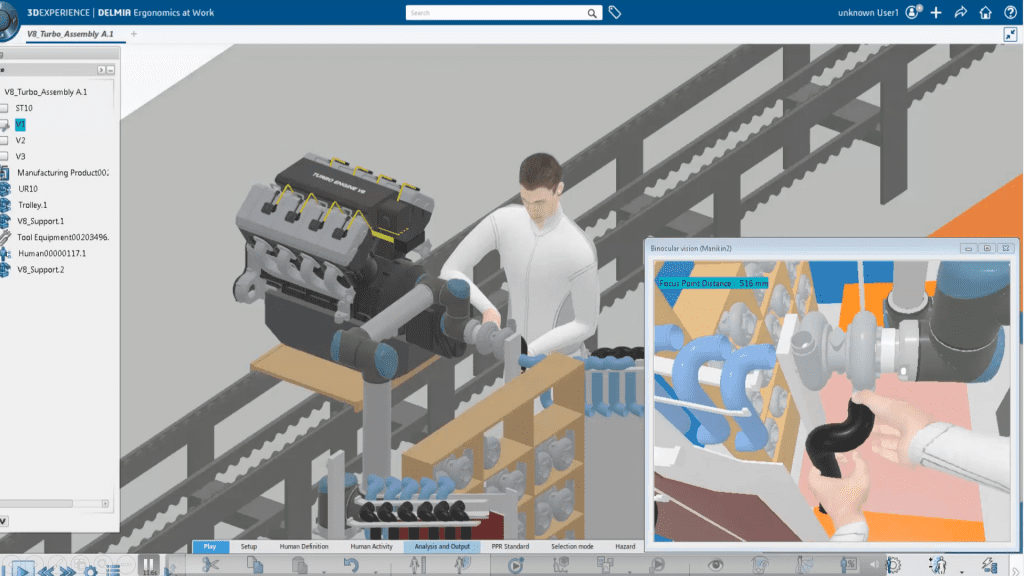

Human-Robot Collaboration

Portable and versatile collaborative robots can improve production operations.

Not only are they specially designed to collaborate with humans in the same working environment, but they are also safer.

Collaborative robots can be easily programmed to execute diverse tasks and you can do so without previous experience.

For effective execution of redeployment and fast deployment tasks, collaborative robots are ideal.

Today, the industry is abandoning centralized manufacturing for distributed manufacturing systems.

This has increased the popularity of cobots due to their flexibility in handling production tasks and lowering chain supply costs.

Transformational Technology

Robot original equipment manufacturers (OEMs) continue to develop transformational technologies that offer enhanced efficiency, consistency, and quality. Industry 4.0 expedited this innovation to offer efficient production. Consider these latest components.

- Lightweight Intuitive Teach Pendants

New and advanced teach pendants are conveniently designed to minimize programming challenges.

Further, they come with instinctive interfaces complete with touch screens making them easy to program. These pendants come with different convenient features.

For instance, they have different user levels to accommodate varied skillsets while offering exclusive display options for distinct applications.

They are easy to use and this has come in handy to propel collaborative and industrial robots to the next level.

Intelligent pendants are specially designed with state-of-the-art human-machine interface features.

Further, they also come with unique tools to make robot machine tending programming easier and more intuitive.

Simple Machine Tool Interfaces

The Great Tech Panic: Robots Won’t Take All Our Jobs

A machine tool should be well designed to facilitate communication with the robot. This will guarantee the ultimate cycle time and safety.

Multiple machine signals are designed to ensure the robot understands the task ahead. These include: “vice is closed”, “door is open”, and “part is in place”

Some machines can be directly linked to a machine tool through a factory connection option. However, many of them should be configured with a communication channel such as Ethernet I/P.

Adaptable Workcell Options

Some small and medium-sized manufacturers in low volume, high mix production environments often stop the equipment to switch components.

As a result, they end up losing lots of time. These businesses can benefit from using easy to load, flexible, and straight forward systems.

Different robot system integrators have developed a pre-engineered robotic machine tending system to facilitate reliable and timely part loading and unloading.

These components come with a user-friendly interface and step by step interfaces for fast use.

New concepts and technological advancements in 3D vision are designed to improve the robotic handling of diverse parts.

Businesses can benefit from the efficient handling of randomly bestowed parts and loading and unloading tasks to eliminate bottlenecks and enhance production.

Finally

Robotic machine tending can increase value to operations in various ways. By considering the concepts discussed here, businesses will eliminate challenges, become more productive, and make more profits.